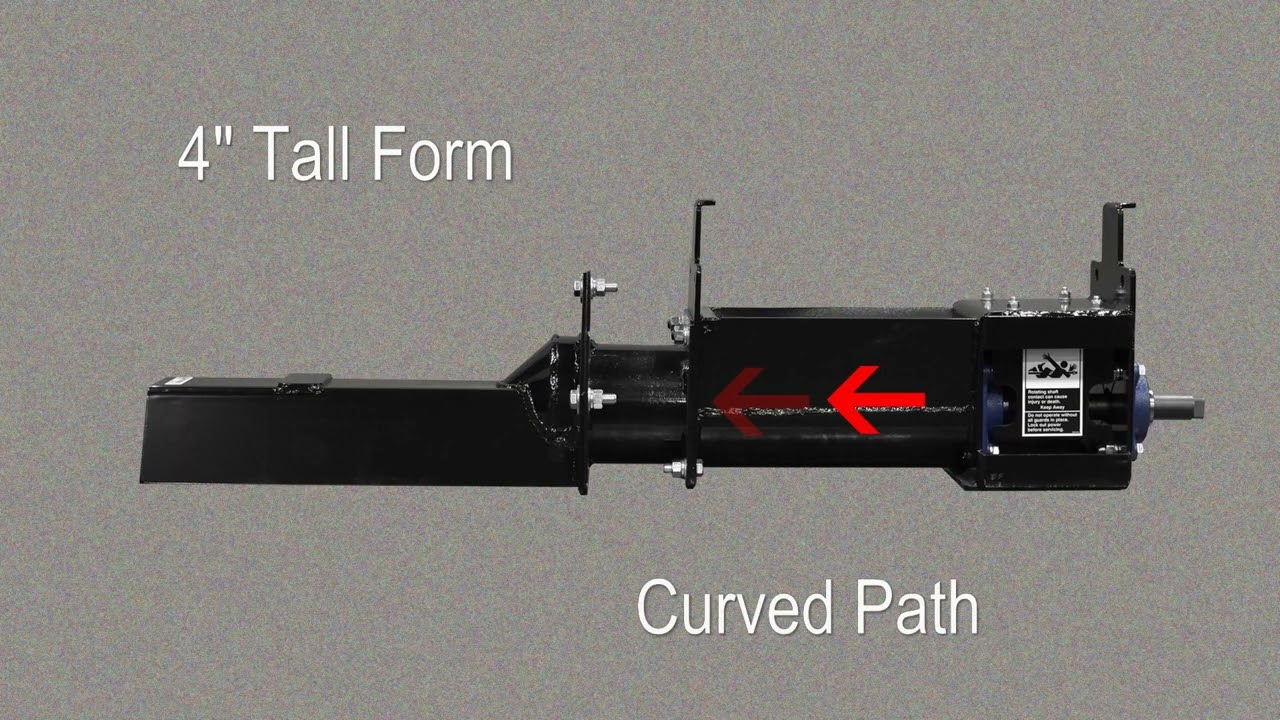

Small curbs (anything less than 5″ in height) can be difficult to extrude because every revolution the auger makes it will attempt to put more material into the curb form than the curb form can handle. In order to be able to get the material into the curb form the machine pushes material both downward and forward, this downward pressure creates back pressure. Back pressure has several symptoms, one of them is excessive wear on components such as augers, compaction tubes and the transition area of the form. Other factors will effect back pressure are the material being extruded, how much curb has to be put down and terrain. Miller Curber has extensive knowledge in dealing with back pressure and we can offer some solutions to help reduce the amount of wear on components when dealing with small forms.

View More How To’s for your Miller Curber Curb Machine.