What are the goings on at Miller Curber Company?

-

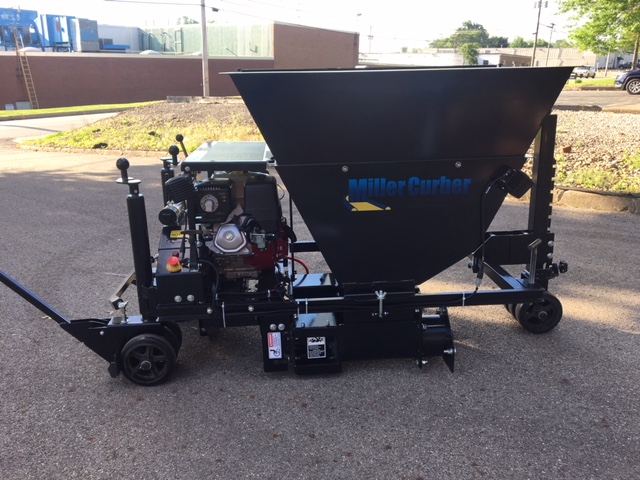

Unique 650

We would like to thank our friends at Asphalt Solutions for the opportunity to build a pretty unique 650. First they wanted it to be all black, next they wanted a custom extension on the hopper, finally they wanted a light kit so night time curbing. Here are some pics of the final product.

-

Hydraulic Braking System

Curb machine with hydraulic brake option. Miller Curber curb extruder.

-

Stone Curb

Here are pictures of some curb that was installed with one of our machines. This is a commercial curb with a decorative appeal. The customer used smaller stone (a lot of it), laid the curb and then came back a few hours later and used a pressure washer to expose the stone. If you are

-

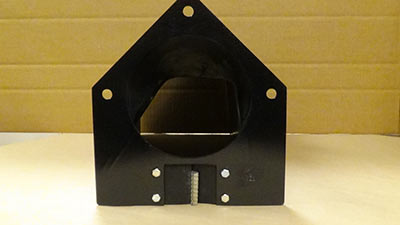

18″ Trench Curb and Pins

Here is a situation where the customer needs to extrude over an 18″ wide trench with a 3″ high pin. This machine was designed to extrude a curb that is 12″ L, 10″ H and has a 6″ flat spot on top of it. In order to do this we had to move the front

-

Curbed Pin

In order to extrude curb over pins a special curbform is required. It requires the curb height to be at least 5″ greater than the pin height. For example, if the pin height is 2″, the curb needs to be at least 7″ high. The additional height allows for the centerline of the auger to

-

Tail Wheel Outrigger

The Tail Wheel Outrigger option allows an operator to stabilize the curb extruder for a variety of job conditions. If a front wheel assembly is offset to accommodate rebar; if a wide curb is being extruded and the tail wheel is moved severely off-center, or if curb is being laid in a trench—the Tail Wheel