What are the goings on at Miller Curber Company?

-

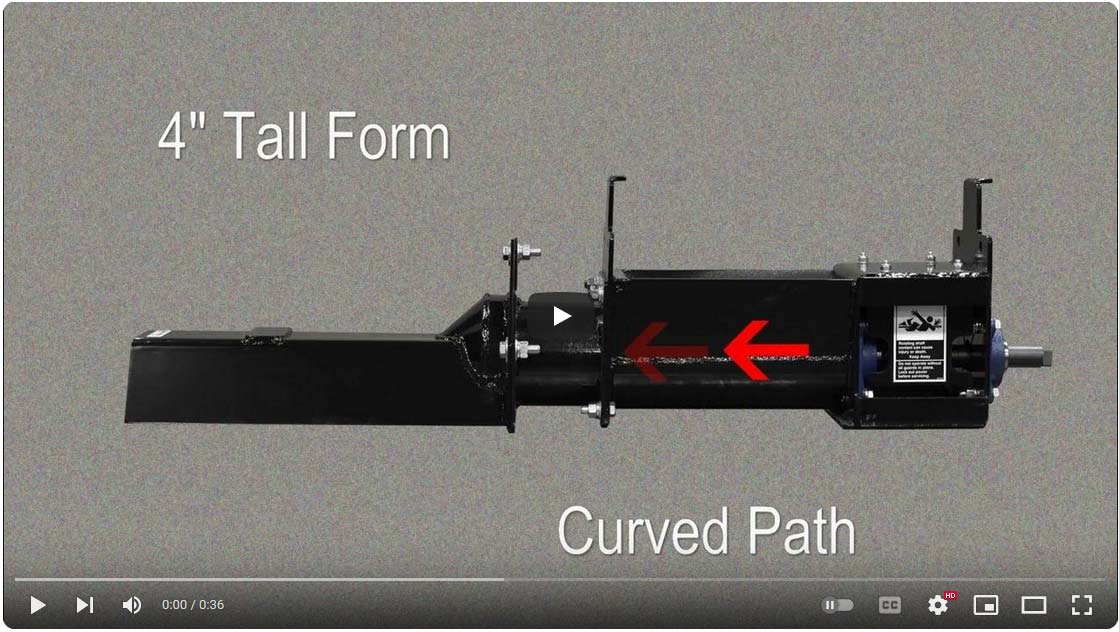

Why Small Curbs are Difficult to Extrude

Small curbs (anything less than 5″ in height) can be difficult to extrude because every revolution the auger makes it will attempt to put more material into the curb form than the curb form can handle. In order to be able to get the material into the curb form the machine pushes material both downward

-

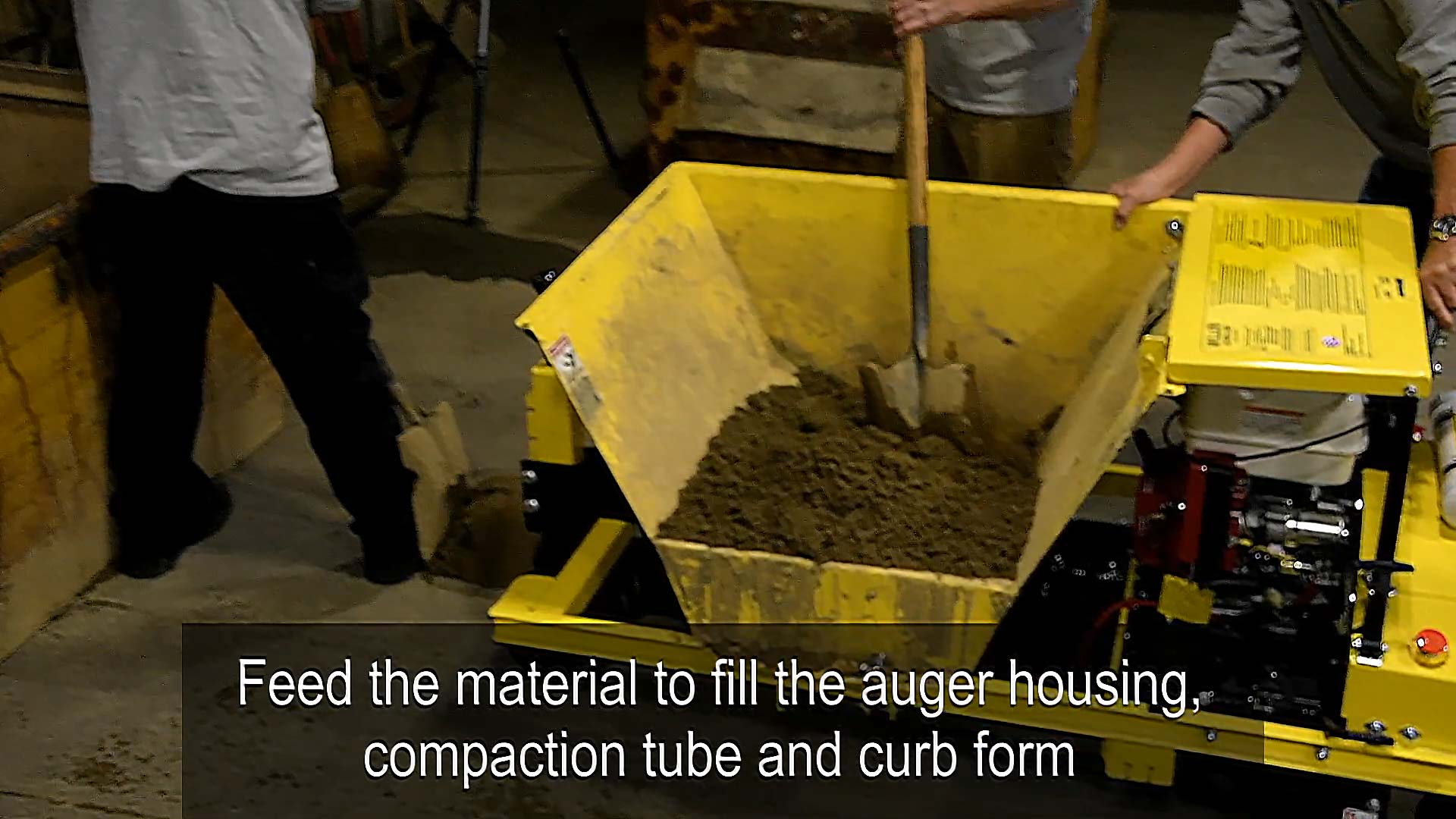

How To Videos

We have a number of new How To videos on our Website [How To Videos], and on our new Miller Curber You Tube Channel, please subscribe. Getting Started Step by Step

-

MC 900 24” Curb and Gutter

Testing a MC 900 built for 24″ curb and gutter with sand. See all our curb and gutter offerings, from 14″ to 24″ >

-

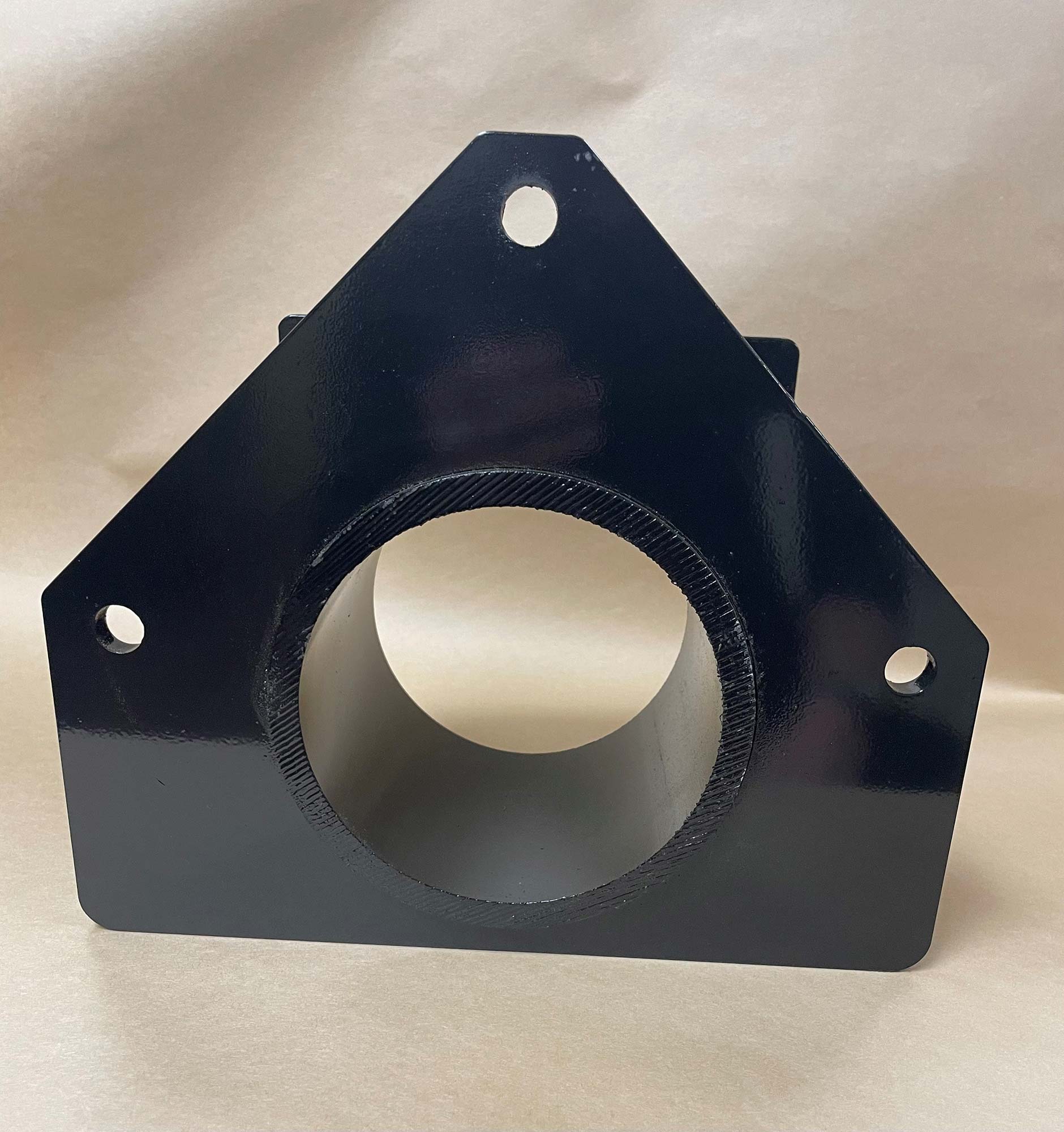

5” Heavy Duty Steel Compaction Tube:

This 5” compaction tube is made from 3/8” steel (both the tube and the flanges) and will last twice as long as our standard 5” compaction tube. This tube is ideal if you are doing a lot of small curbs (4” and below) where the machine will have a lot of back pressure in it.

-

Why buy a Miller Curber?

For its versatility. Our machines have the capability to extrude big forms (such as this 18″ tall curb) and smaller forms typically used in parking lots.

-

MC 900 Dual Auger Machine

The MC 900 dual auger machine is designed to extrude either a 18” or 24” curb and gutter. This machine is built with 2 auger housings next to each other. If you would like to do a 24” curb and gutter (CFD-1887), the machine is equipped with a 2-8” auger housings. If you would like